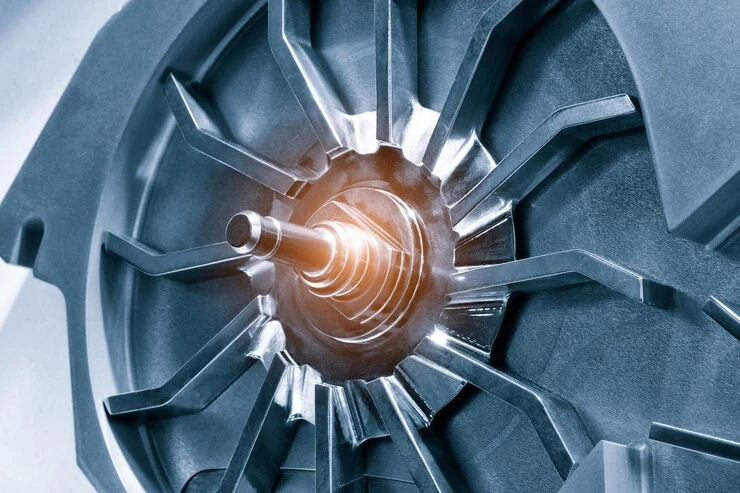

At Sterling Technocast, we specialize in producing high-quality impeller castings that meet the exact requirements of various industries. As a trusted impeller casting manufacturer, we ensure that every impeller is designed with precision, durability, and superior performance in mind.

Our engineers carefully analyze casting techniques to determine the most suitable method for manufacturing impellers based on performance, material selection, and application requirements. With a focus on quality and innovation, we deliver high-performance impeller castings that enhance the efficiency and reliability of pumps and fluid-handling systems.

Specialized Impeller Castings We Manufacture

Sterling Technocast has expertise in producing non-ferrous impeller castings in various materials, including:

Silicon Brass & Silicon Bronze Impellers

High corrosion resistance for marine and industrial applications.

Lead-Free Impellers for Drinking Water Applications

Ensuring safety and compliance with potable water standards.

Ni-Resist Impellers

Superior wear resistance and thermal stability for extreme environments such as in artificial lifts of Oil and gas industries.

We manufacture impellers with precise dimensional accuracy and smooth surface finishes, ensuring optimal hydraulic efficiency and long service life.

Industries We Serve

Due to their superior properties, our impeller castings are widely used in:

Oil & Gas Industry

High-performance impellers for critical fluid movement applications.

Aerospace Industry

Precision impellers designed for aviation and space technology.

Renewable Energy Sector

Used in solar thermal and hydropower systems for efficient heat transfer.

Drinking Water & Wastewater Treatment

Lead-free impellers for safe water handling.

Chemical & Marine Industry

Corrosion-resistant impellers in silicon bronze and Ni-Resist for aggressive environments.

Our Commitment to Quality & Innovation

At Sterling Technocast, we continuously improve our casting techniques by integrating modernized technologies. Our state-of-the-art facility ensures that every impeller casting meets global industry standards while maintaining cost-effectiveness.

Why Choose Sterling Technocast for Impeller Castings?

- Expertise in Non-Ferrous Alloy Impellers – Specialized in silicon brass, silicon bronze, Ni-Resist, and lead-free impellers.

- Investment Casting Precision – We use investment casting to produce high-accuracy impellers with complex geometries and minimal post-machining requirements.

- Customization & Technical Support – Our engineers collaborate with customers to design impellers tailored to their specific needs.

- Advanced Manufacturing & Testing – In-house chemical & mechanical analysis, CMM inspection, and non-destructive testing (NDT) ensure quality and consistency.

- On-Time Delivery – We prioritize timely production and delivery without compromising on quality.

Our Core Values

- Customer Commitment – We deliver high-quality impeller castings that meet or exceed customer expectations.

- Collaborative Approach – Our teamwork-driven manufacturing process ensures customized solutions.

- Continuous Learning & Innovation – We constantly refine our techniques and adapt to new industry trends.

- Efficient Resource Utilization – We maximize raw material efficiency while maintaining superior casting quality.

- Reliable & Timely Supply – Our streamlined manufacturing and logistics ensure on-time delivery worldwide.

Looking for a reliable Impeller Casting Manufacturer?

At Sterling Technocast, we provide high-performance, corrosion-resistant impellers designed to meet your industrial demands. Contact us today to discuss your custom impeller casting requirements!